The Unchaining of Supply Chains: Dismantling Disruption and Risk in the Post-COVID World

Seven Forces Reshaping the Economy

As the historic 2020 U.S. presidential election approaches, the economy continues to rank as voters’ top issue – coming as no surprise given the unprecedented economic turmoil caused by the COVID-19 pandemic. In this seven-part series of Kenan Insights, we offer a current and in-depth analysis of the findings in our latest report, which explores the economic challenges and opportunities facing our nation amid and beyond both the election and the pandemic. The Kenan Institute of Private Enterprise, in partnership with the North Carolina CEO Leadership Forum, has issued Seven Forces Reshaping the Economy to help decision-makers navigate these critical trends and offer pragmatic solutions to the economic shifts that are defining our new normal. This week we look at how the pandemic has disrupted global supply chains and, as a result, what strategies companies are using to mitigate risk moving forward.

Even prior to the COVID-19 pandemic, corporate executives were faced with a growing menace to the global supply chain due to rising external threats. Heated trade tensions between the United States and China, as well as complex Brexit negotiations, hinted at a budding movement toward economic nationalism in countries around the globe.1 In a world reliant on complex supply networks, these transnational political tensions exposed the vulnerabilities of modern globalization.

Then COVID-19 materialized in China. Immediately, the anticipated threats to global supply chains were being realized.2 The initial supply chain shock derived from the closure of manufacturing facilities in Asia,3 but quickly migrated to interruptions in transportation and the closure of domestic facilities with the proliferation of stay-at-home orders and outbreaks in facilities such as meat processing plants.4 In addition, significant increases in demand for some items such as PPE, cleaning supplies, food to be consumed at home, and delivery and transportation services resulted in widespread shortages (such as the infamous toilet paper scare). To read more about the healthcare supply challenges in the early days of the pandemic, see: Where Did All the PPE Go? The COVID-19 Disconnect Between Hospitals and the Healthcare Supply Chain.

Disruption Spotlight: The American Agricultural Supply Chain

One of the sectors severely impacted by a domino effect caused by trade wars, the global pandemic and other external factors is the American agricultural supply chain. By June 2020, farm bankruptcies had already increased by 8 percent compared to 2019, even though federal aid was, and continues to be, at historic highs.5 Due to social distancing requirements and immigration restrictions, farmers are likely to continue to struggle to find sufficient workers.6 In addition, with a potential labor shortage and existing farm workers’ increased potential for contracting COVID-19, farmers may be unable to pay higher wages to attract workers.

Disruptions to food processing further compound the challenges. The closure of meat processing facilities due to COVID-19 outbreaks has led to meat distribution shortages, adding additional strain on the food supply chain. From April 2019 to April 2020, livestock processing decreased 40 percent, a slowdown that has led some farmers to euthanize their stock to prevent massive overcrowding.7 A diminished food supply has the potential to inequitably affect underprivileged communities, possibly exacerbating already raw social tensions (see next section). Finally, the stability of the nation’s agricultural infrastructure could face further disruption if relations between the U.S. and certain trading partners continue to deteriorate.

Mitigating Supply Chain Risks with Agility and Resiliency

In response to these mass disruptions, companies have undertaken full-spectrum analyses of their supply chains with an eye to two primary considerations: agility and resiliency.8

To ensure more agile operations when faced with external shocks, companies are seeking to source critical components (including labor) from more flexible suppliers and bring more of their operations in house.9 As the COVID-19 pandemic has demonstrated, unforeseen events can trigger major disruptions to entire supply chain networks. Many global companies had failed to implement effective business continuity plans, operating instead under the assumption that their supply chain designs would somehow allow materials and services to flow freely around the globe and enable them to continue operations while leveraging the lowest-cost global locations.

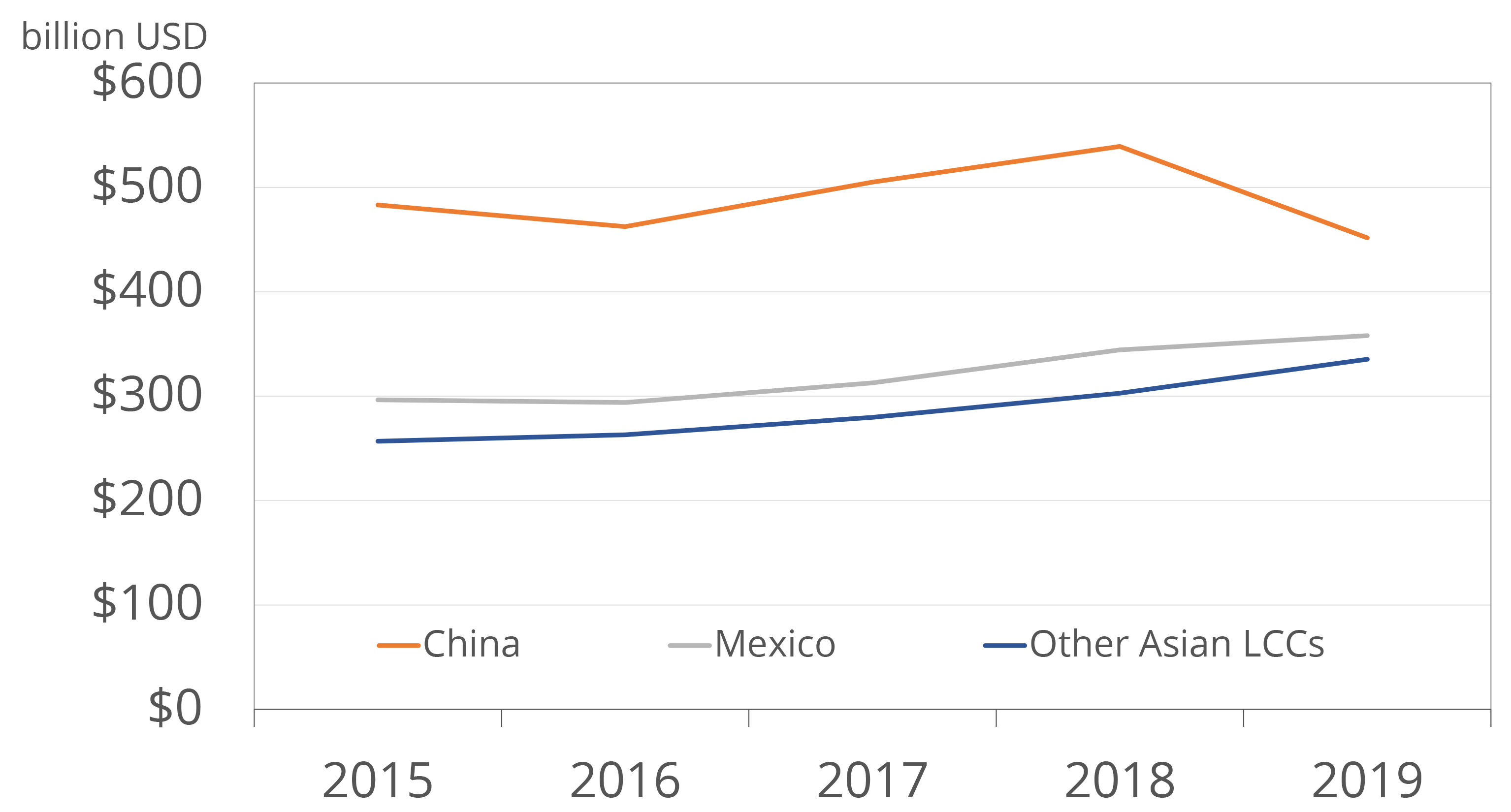

In the wake of the pandemic, companies are also looking to increase their resiliency to future shocks. To build up this resiliency, they are finding ways to simplify logistics in order to make abrupt changes easier to manage. Additionally, companies are making operations more robust to external shocks by moving production closer to markets and increasing buffers (e.g., inventories). Notably, in the last year there has been more measurable movement away from manufacturing in China and toward other low-cost Asian countries, near-shoring in Mexico and onshoring in the United States after a decade of growth. These trends started prior to the pandemic and will likely accelerate. From 2018 to 2019, U.S. manufacturing imports from China decreased by roughly $90 billion (a drop of 17 percent).10 In turn, manufacturing imports from other Asian low-cost countries and Mexico rose by $31 billion and $13 billion, respectively.11

Other Asian Low-cost Countries (LCCs): Vietnam, Philippines, Malaysia, Indonesia, Pakistan, Sri Lanka, Taiwan, Thailand, Bangladesh, India, Singapore, Hong Kong, Cambodia

Leveraging the Power of Technology

To make their supply chains more agile and resilient, companies will become increasingly reliant on systems based on newer and disruptive technologies that help build smarter supply chains and reduce vulnerabilities during global pandemics and other unforeseen circumstances. Smarter supply chains that leverage the power of artificial intelligence (AI), the internet of things (IoT) and blockchain capabilities, among others, will help companies maintain business continuity amid disruption and uncertainty. This not only allows these companies to closely monitor their supply chains in real time; it also helps them predict possible vulnerabilities and disruptions and understand their up- and downstream impacts, enabling more rapid responses.

Leveraging technology, near-shoring and increased supply chain fluidity will help with rapid responses and issue resolution, limiting disruptions due to unforeseen circumstances. In addition, companies have become more aware of secondary and tertiary supply chain dependencies, especially their reliance on China.12 While the trend in recent years had been toward more efficient supply chains, the focus has now shifted to making those supply chains more robust. The results of these changes will include near-shoring and onshoring more production (and expanding existing domestic facilities), diversifying supplier relationships, investing further in inventories and materials, relying more on sophisticated technological solutions and bringing certain operations in house (through de novo operations or vertical mergers and acquisitions).

1 Allen, A. (2018, November 28). Manufacturers would change supply chains due to economic nationalism. Supply Management. Retrieved from https://www.cips.org/supply-management/news/2018/november/manufacturers-would-change-supply-chains-due-to-economic-nationalism/

2 Bank of America (2020). Tectonic shifts in global supply chains. Bank of America Global Research. https://www.bofaml.com/content/dam/boamlimages/documents/articles/ID20_0147/Tectonic_Shifts_in_Global_Supply_Chains.pdf

3 Mickle, T. (2020, February 1). Apple Closes Chinese Stores, Corporate Offices Due to Coronavirus. The Wall Street Journal. https://www.wsj.com/articles/apple-closes-chinese-stores-corporate-offices-due-to-coronavirus-11580580600. For example, Apple closes facilities in China.

4 Areddy, J. T. (2020, February 3). Coronavirus Closes China to the World, Straining Global Economy. The Wall Street Journal. https://www.wsj.com/articles/coronavirus-closes-china-to-the-world-straining-global-economy-11580689793

5 Newman, Jesse. (2020). More Farmers Declare Bankruptcy Despite Record Levels of Federal Aid. The Wall Street Journal. https://www.wsj.com/articles/more-farmers-declare-bankruptcy-despite-record-levels-of-federal-aid-11596706201?mod=hp_lista_pos1

6 Felix, I., Martin A., Mehta, V., and Mueller, C. (2020). US Food Supply Chain: Disruptions and Implications from COVID-19. McKinsey. https://www.mckinsey.com/industries/consumer-packaged-goods/our-insights/us-food-supply-chain-disruptions-and-implications-from-covid-19

7 OECD (2020). Food Supply Chains and COVID-19: Impacts and Policy Lessons. https://read.oecd-ilibrary.org/view/?ref=134_134305-ybqvdf0kg9&title=Food-Supply-Chains-and-COVID-19-Impacts-and-policy-lessons

8 Sheffi, Y. (2020). Who Gets What When Supply Chains Are Disrupted? MIT Sloan Management Review. Retrieved August 21, 2020, from https://sloanreview.mit.edu/article/who-gets-what-when-supply-chains-are-disrupted/

9 Maidenberg, M. (2020, April 26). Fewer Products, Localized Production—Companies Seek Supply-Chain Solutions. The Wall Street Journal. https://www.wsj.com/articles/coronavirus-disrupted-supply-chains-that-companies-are-still-fixing-11587893401

10 Van den Bossche, P., Castano, Y., Levering, B. & Blaesser, B. (2020). Trade war spurs sharp reversal in 2019 Reshoring Index, foreshadowing COVID-19 test of supply chain resilience. Kearney. Retrieved from: https://www.kearney.com/operations-performance-transformation/us-reshoring-index/full-report

11 Ibid.

12 Shih, W. (2020, March 19). Is It Time to Rethink Globalized Supply Chains? MIT Sloan Management Review. https://sloanreview.mit.edu/article/is-it-time-to-rethink-globalized-supply-chains/